New product development case

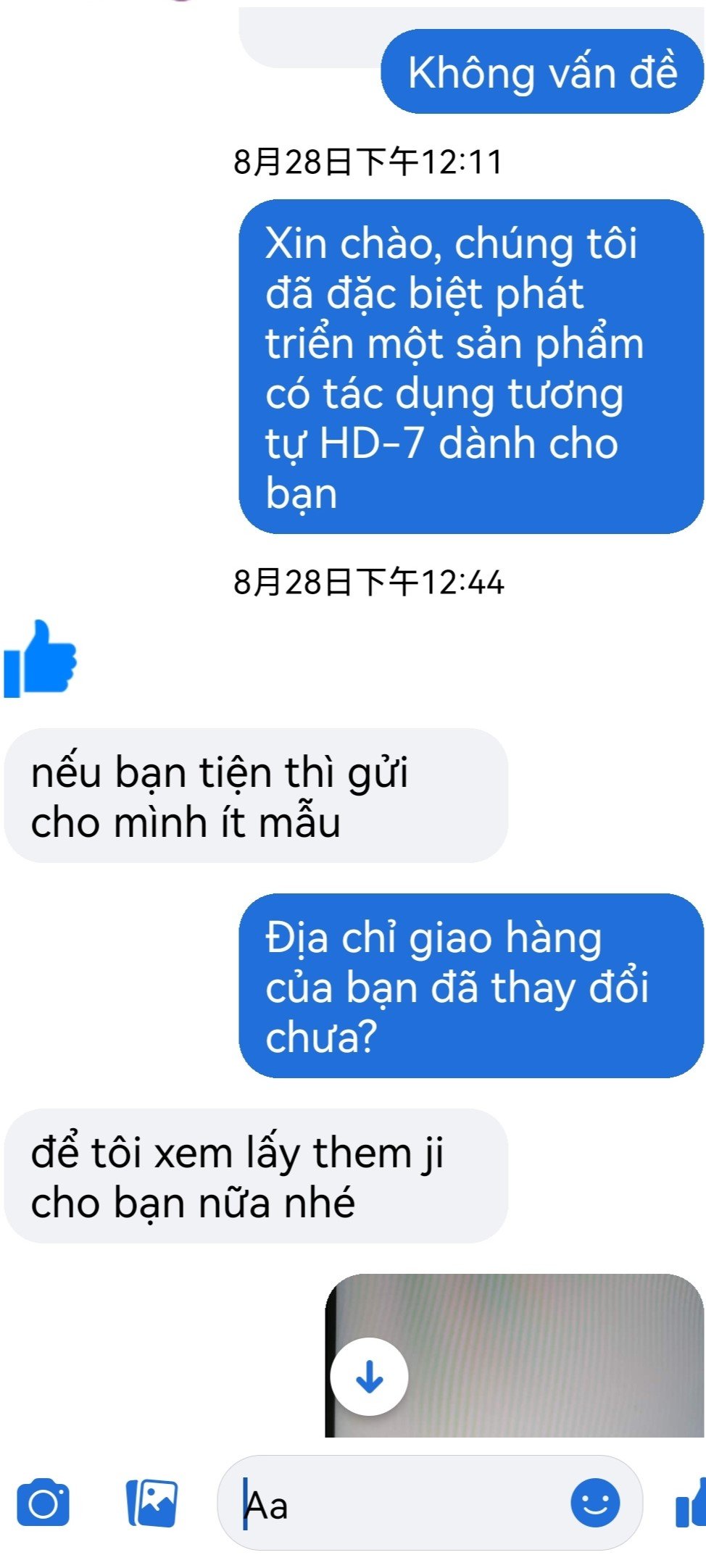

Develop products based on customer needs

Technical implementation path: Flavor design: Food engineers match or reorganize flavor modules from the basic formula library according to customer needs (such as Southeast Asian hot and sour base + low-salt health adjustment) Sample testing: Provide 3-5 versions of laboratory samples to support customers in application testing (such as compatibility with customer terminal products, high temperature resistance/freezing performance) Quick iteration: Respond to feedback within 72 hours and adjust parameters such as saltiness, sweetness, aroma level, texture, etc. until they meet the standards

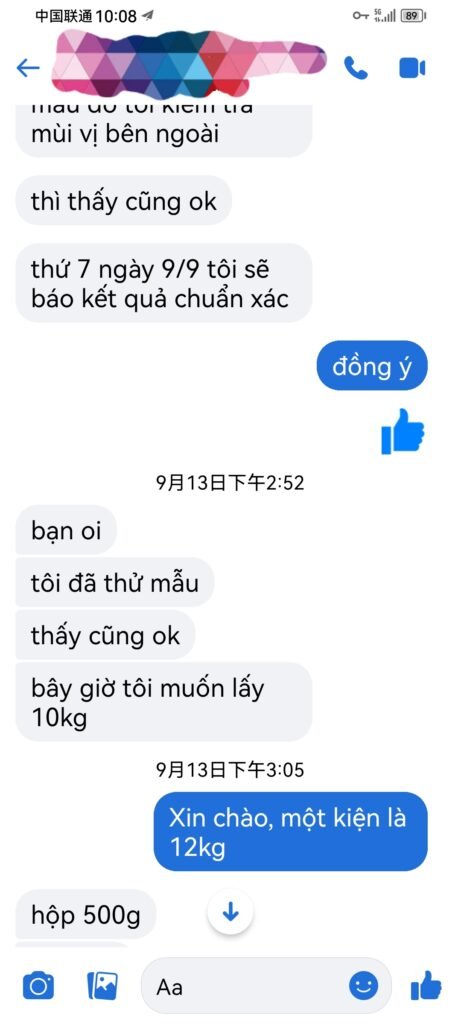

Product development is successfully delivered to customers for testing

Multi-dimensional evaluation mechanism: Laboratory testing: customer quality inspection team verifies product stability (accelerated shelf life test/freeze-thaw cycle experiment) Production adaptation test: pilot test on customer's actual production line (testing compatibility of condiments and filling equipment) Consumer blind test: collect end-user feedback through customer channels (preference ≥7.5/10 is considered passed) Competitive product benchmarking analysis: provide horizontal comparison report with mainstream products in the market (cost advantage + sensory score)